Spare parts

Receiving System

Moving System

Screening System

Processing System

Storage System

Extracting System

Turnkey Pellet Plant

Spare Parts

Our partners

Distributor and Feeder Assembly

See all >Bucket Elevator

See all >Disc Sorting Screen

See all >Crusher

See all >Screw Reclaimer Supported at Both end With External Drive

See all >Screw Reclaimer Supported at Both end With Internal Drive

See all >Travelling Screw Reclaimer

See all >Swinging Screw Reclaimer

See all >Screw Conveyor

See all >Redler Drag Conveyor (Biomass)

See all >Redler Drag Conveyor (Ash)

See all >Redler Drag Conveyor (Distributor)

See all >Belt Conveyors

See all >Belt Conveyors (Gutter)

See all >Belt Conveyors (Tripper)

See all >Cleated Drag Hopper

See all >

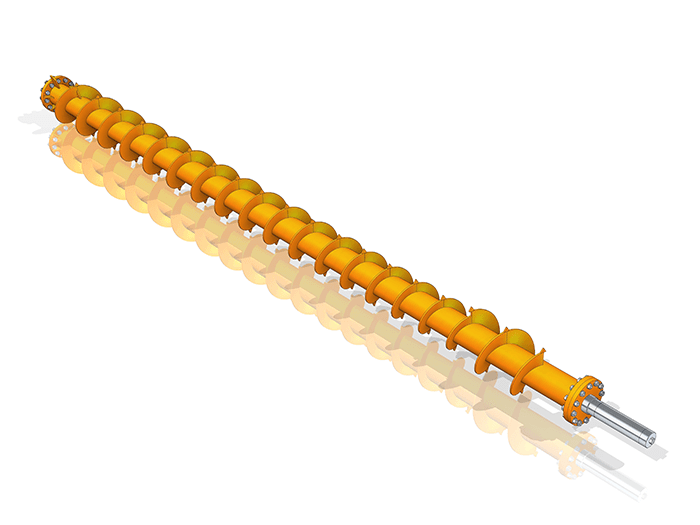

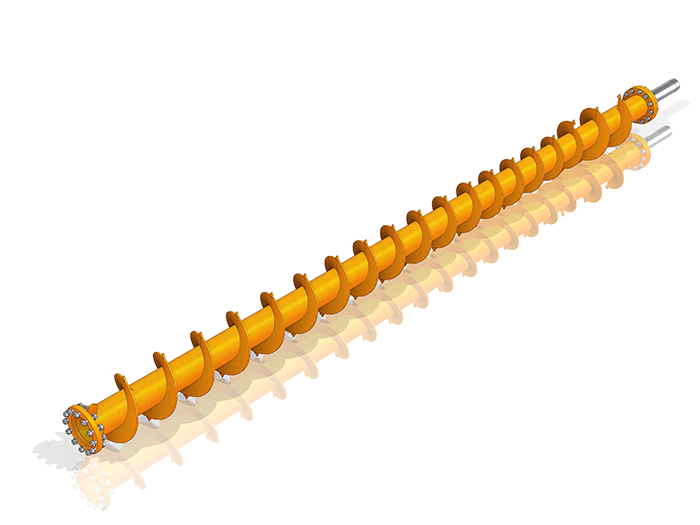

Extracting System | Screw Reclaimer Supported at Both end With External Drive

Coil

Developed by our engineering department, following Dujua standard manufacturing and quality criteria. A wide variety of material types and manufacturing processes can be applied in order to ensure a longer service life and high productivity even in the harshest environments. Examples:

- Fins made of Hardox® wear-resistant material, which is the best abrasion-resistant steel, with uniform hardness from the surface to the core of the sheet.

- High-hardness welded lining at the edge of the fins, conveyor side and tube region where it comes into contact with the material to be transported.

- Shafts developed in special alloys according to the needs of each project.

Our spirals undergo strict quality control in the manufacturing process, the shafts are inserted under hydraulic pressure, and after the welding process, all spirals undergo a concentricity realignment process. This process is necessary to ensure full alignment of the mechanical assembly of components in which each spiral model is mounted.