Extracting Screw

Robust equipment with easy access for maintenance, designed for continuous operation and precise dosing.

The extracting screw is an equipment designed to extract and dose various types of biomass from vertical and horizontal silos, conveying them to the feeding system.

The movement of the biomass is carried out by helical blades, using simultaneounsly translational (pneumatic) and rotational (electric) movements, which allows continuous or intermittent extraction, avoiding the formation of empty channels (tunnels or caves).

In order to increase the lifespan of the equipment, special materials can be applied in its construction, such as Hardox or stainless steel screws, or mig welding hardfacing overlays on the surfaces of the screws that come into contact with the biomass.

The screw model, as well as the installed power, is determined not only by the equipment’s flow rate but also by the storage capacity and the size of the silo in which the screw is installed.

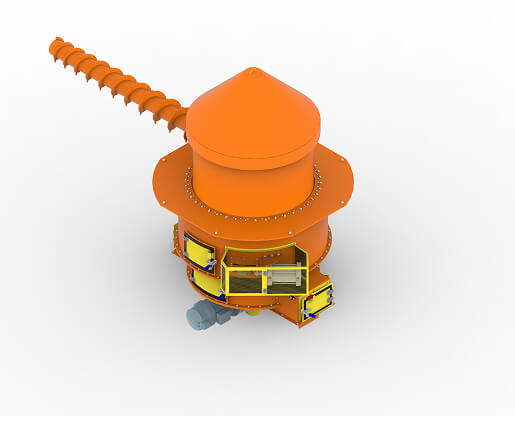

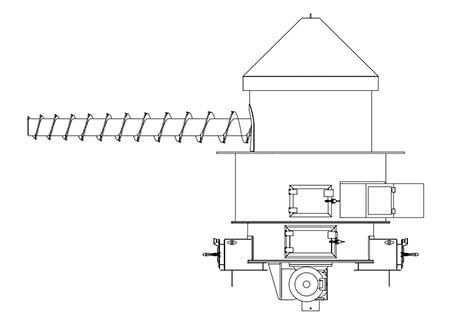

Cantilevered Extracting Screw

It is usually installed in small and medium vertical silos, with varying dimensions, flow rates, and storage volumes, depending on the project's requirements.

The rotation of the extracting screw is driven by an electric motor, with power transmission provided by a universal joint and a 90° reduction gearbox (Dujua manufacturing). The translational movement is operated by a pneumatic system installed within the equipment's body.

This extracting screw model also features an agitator system, responsible for directing the biomass to the discharge point. The agitator is driven by the same electric motor that controls the screw’s rotation.

Technical specifications

| Models | RED/B-810 | RED/B-1000 | RED/B-1200 | RED/B-1500 | RED/B-1800 |

|---|---|---|---|---|---|

| Diameter (mm) | 200 to 300 | 300 to 400 | 300 to 500 | 300 to 600 | 400 to 800 |

| Length (mm) | 2.000 to 2.300 | 2.000 to 2.900 | 2.000 to 3.450 | 2.900 to 3.450 | 3.300 to 4.950 |

| Power (HP) | 7,5 to 12,5 | 12,5 to 20 | 12,5 to 25 | 15 to 40 | 20 to 50 |

| Flow rate (m³/h) | 10 to 30 | 30 to 50 | 50 to 100 | 100 to 200 | 200 to 300 |

| Weight (kg) | 2.500 | 3.800 | 5.700 | 6.900 | 10.100 |

The equipment can be adjusted according to your project's needs.

Internally Driven Bi-supported Extracting Screw

It is usually installed in medium and large vertical silos, with large dimensions, flow rates, and storage volumes, depending on the project's requirements.

Similar to the cantilevered extracting screw, its rotation movement is driven by an electric motor located inside the equipment, while the translational movement is operated by a pneumatic system installed on the external area, at the edge of the silo’s circumference.

This extracting screw model also includes an agitator system, which directs the biomass to the discharge point. The agitator is driven by the same electric motor that controls the screw’s rotation.

Technical specifications

| Models | RED/BI-AI-1200 | RED/BI-AI-1500 | RED/BI-AI-1800 |

|---|---|---|---|

| Diameter (mm) | 300 to 500 | 300 to 600 | 400 to 800 |

| Length (mm) | 7.000 | 7.000 | 8.000 |

| Power (HP) | 30 to 50 | 40 to 75 | 40 to 75 |

| Flow rate (m³/h) | 50 to 100 | 100 to 200 | 200 to 300 |

| Weight (kg) | 8.000 | 9.000 | 16.000 |

The equipment can be adjusted according to your project's needs.

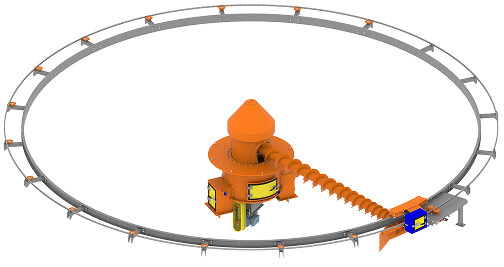

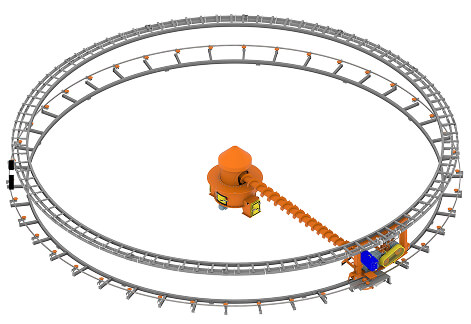

Externally Driven Bi-supported Extracting Screw

It is usually installed in vertical silos with large dimensions, flow rates, and storage volumes.

The extracting screw is supported at the central point and on a carriage that slides around the silo, and is activated pneumatically. In this configuration, both the electric drive system (rotation) and the pneumatic drive system (translation) are installed externally, which facilitates maintenance access.

This extracting screw model features an agitator system, which is driven by a second electric motor, independent of the motor responsible for the rotation.

Technical specifications

| Models | RED/BI-AE-1200 | RED/BI-AE-1500 | RED/BI-AE-1800 | RED/BI-AE-2000 |

|---|---|---|---|---|

| Diameter (mm) | 300 to 400 | 300 to 500 | 400 to 600 | 400 to 800 |

| Length (mm) | 4.800 | 6.000 | 6.900 | 10.900 |

| Screw Power (HP) | 40 to 60 | 40 to 60 | 75 to 100 | 100 to 150 |

| Agitator Power (HP) | 7,5 | 7,5 | 7,5 | 12,5 |

| Flow rate (m³/h) | 50 to 80 | 50 to 100 | 100 to 400 | 130 to 600 |

| Weight (kg) | 8.600 | 13.300 | 16.000 | 20.600 |

The equipment can be adjusted according to your project's needs.

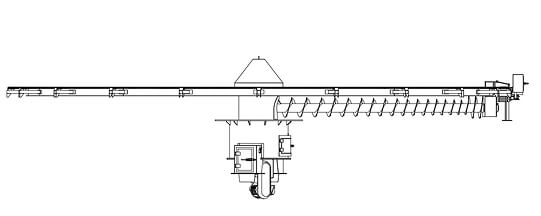

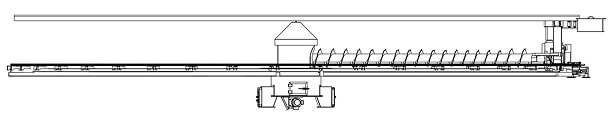

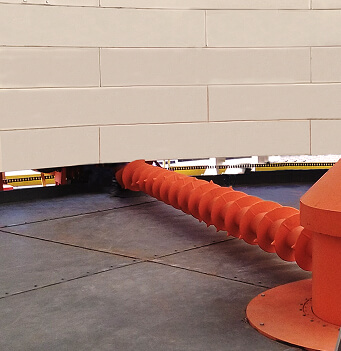

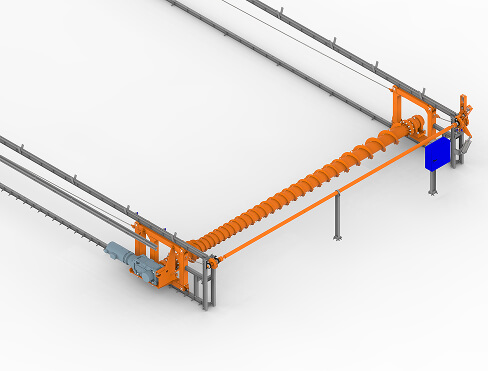

Mobile Extracting Screw

It is usually installed in medium and large horizontal silos, with large dimensions, flow rates, and storage volumes, depending on the project's requirements.

Following the same design concept as the other extracting screws, the rotation system is driven by an electric motor, while the translational movement is operated by a pneumatic system—one of the major uniqueness of Dujua’s extracting screws.

Depending on project's requirements, it is possible to install more than one screw extractor in the same silo.

Technical specifications

| Models | REM/50-D | REM/80-D | REM/100-D | REM/150-D |

|---|---|---|---|---|

| Diameter (mm) | 400 to 500 | 500 to 600 | 600 to 700 | 700 to 800 |

| Length (mm) | 9.700 | 10.500 | 10.700 | 12.600 |

| Power (HP) | 30 to 60 | 60 to 150 | 60 to 150 | 100 to 250 |

| Flow rate (m³/h) | 40 to 65 | 45 to 150 | 60 to 200 | 120 to 450 |

| Weight (kg) | 10.300 | 12.100 | 13.400 | 33.900 |

The equipment can be adjusted according to your project's needs.