Hopper

Robust equipment with easy maintenance access, precise dosing, and continuous operation. Designed to prevent the formation of empty galleries (caverns/tunnels).

The hopper is an equipment designed for receiving, storing, and subsequently discharging/dosing various types of biomass into the moving system. It operates continuously and is adjustable to the industrial flow feeding process.

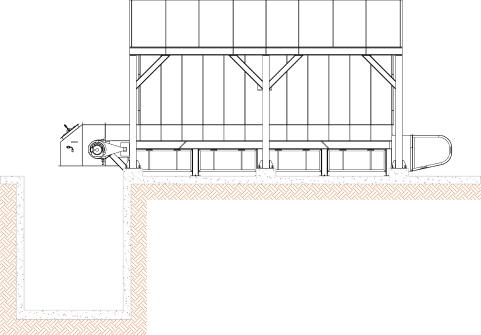

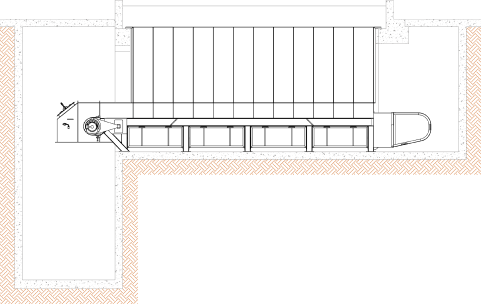

This equipment can be installed underground, at level 0 (pit), for feeding by tipping trucks and moving floor. It can also be installed above ground level for feeding by loader.

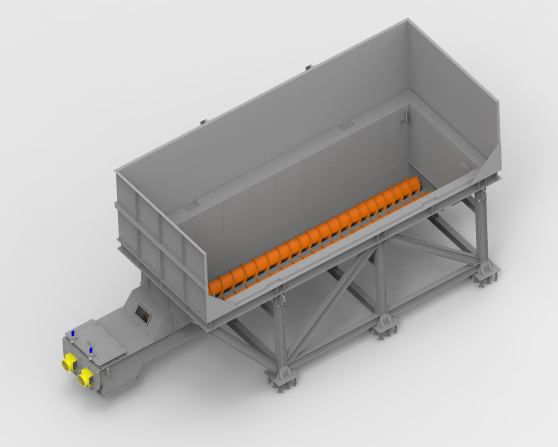

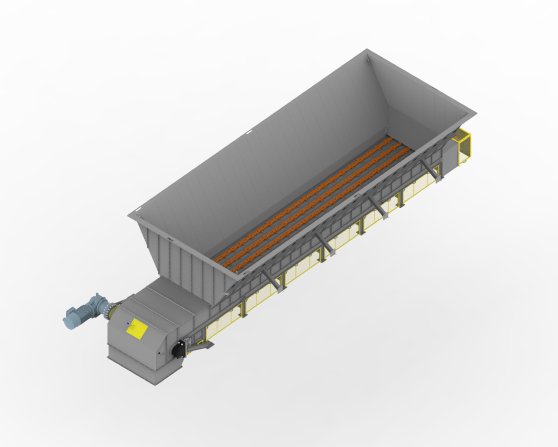

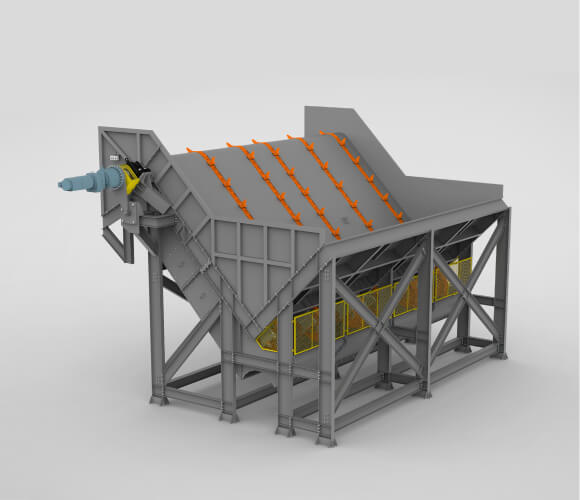

Screw Hopper

In the screw hopper, the material is moved by helical blades.

From 1 to 6 screws can be installed with the sizing varying according to several factors, typically associated with the type of biomass to be conveyed.

Special materials may be applied to its construction to increase its lifespan, such as screws made of Hardox or Stainless Steel, or even mig welding hardfacing on the screw's surfaces that come into contact with the biomass.

Technical specifications

| Models | MRD/15 | MRD/25 | MRD/35 | MRD/50 | MRD/75 | MRD/100 |

|---|---|---|---|---|---|---|

| Screw quantity | 1 to 2 | 2 to 3 | 2 to 3 | 2 to 4 | 2 to 5 | 2 to 6 |

| Storage (m³) | Up to 15 | From 16 to 25 | From 26 to 35 | From 36 to 50 | From 51 to 75 | From 76 to 100 |

| Width (mm) | 1600 to 2300 | 1800 to 2900 | 2200 to 3200 | 2200 to 4500 | 2200 to 4800 | 2200 to 5100 |

| Length (mm) | 2500 to 5100 | 3600 to 7100 | 4500 to 8200 | 5700 to 8900 | 6300 to 9800 | 7900 to 10500 |

| Height (mm) | 1000 to 2100 | 1400 to 2200 | 1700 to 2300 | 1700 to 2800 | 1700 to 2900 | 1700 to 3100 |

| Power (HP) | 5 to 25 | 5 to 25 | 10 to 30 | 10 to 30 | 10 to 50 | 10 to 50 |

| Flow rate (m/h) | 10 to 100 | 15 to 200 | 80 to 200 | 80 to 300 | 80 to 400 | 80 to 500 |

| Weight (kg) | 6.200 | 7.600 | 11.800 | 13.000 | 13.600 | 14.300 |

The equipment can be adjusted according to your project's needs.

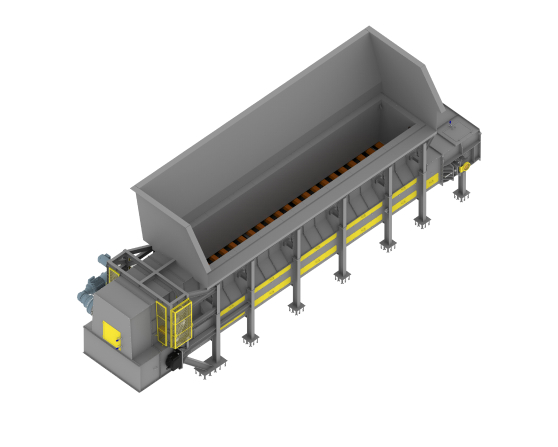

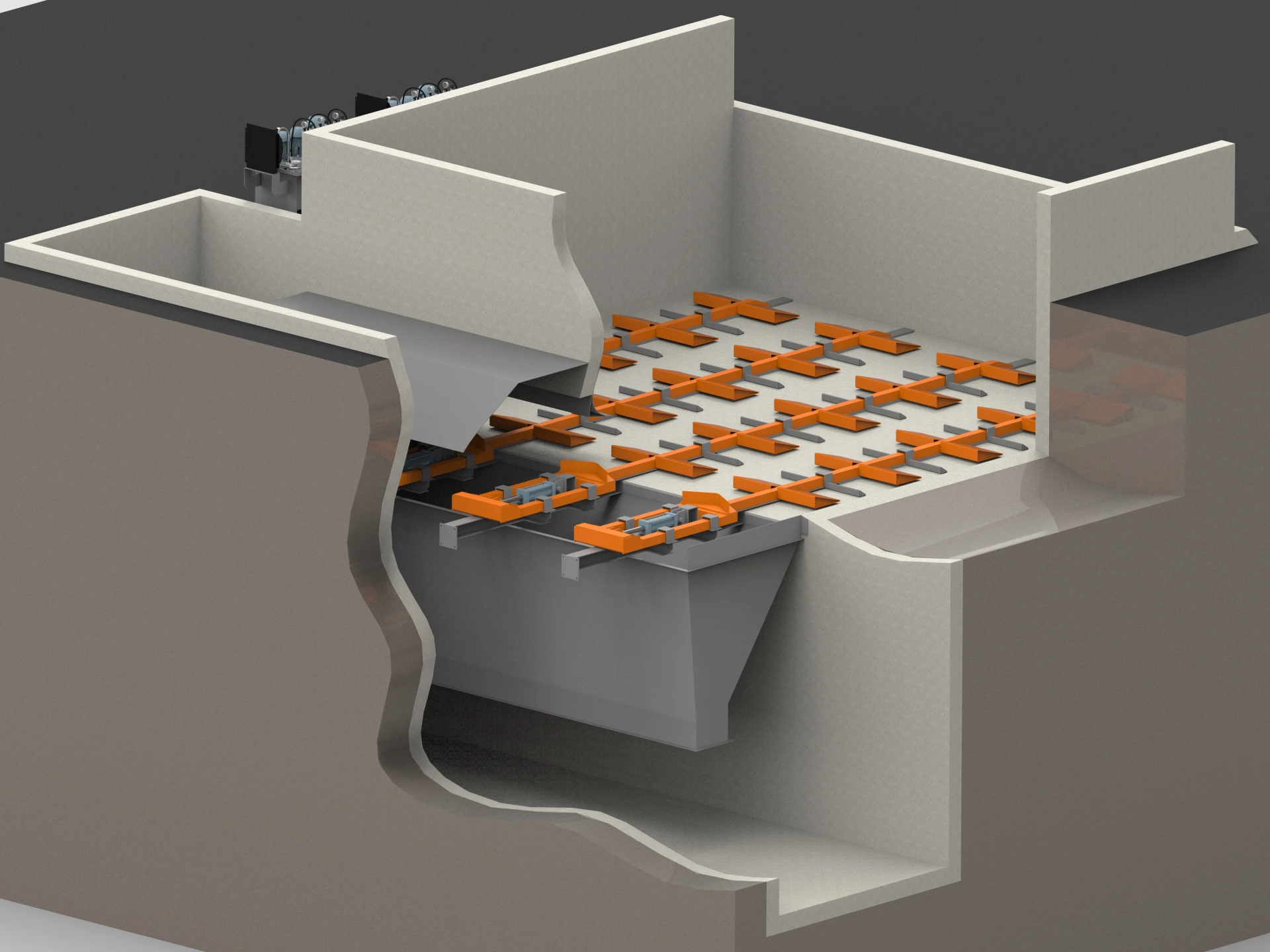

Drag Slat Hopper

Unlike other hoppers, the biomass conveyment in this model is carried out by slats, and it's designed to move materials with greater resistance to flow, such as sugarcane bagasse. This is the uniqueness of this equipment compared with other hopper models.

Special materials are applied in its construction to increase its lifespan, such as internal walls lined up with stainless steel sheets, chain's displacement tracks made of Hardox, and the external structure reinforced with beams. In addition, it is designed so that the chains are isolated in a chamber, preventing direct contact with the biomass. These details and design features ensure the robustness and durability of the equipment.

Technical specifications

| Models | MTAD/20 | MTAD/25 | MTAD/35 |

|---|---|---|---|

| Chain path quantity | 2 | 2 | 2 |

| Storage (m³) | Up to 20 | From 21 to 30 | From 31 to 40 |

| Width (mm) | 2.015 | 2.015 | 2.200 |

| Length (mm) | 9.600 | 9.600 | 10.600 |

| Height (mm) | 1.500 | 1.700 | 1.900 |

| Power (HP) | 30 to 60 | 50 to 75 | 75 to 100 |

| Flow rate (m³/h) | 50 to 400 | 50 to 500 | 50 to 750 |

| Weight (kg) | 29.200 | 33.300 | 39.800 |

The equipment can be adjusted according to your project's needs.

Drag Chain Hopper

The biomass movement is carried out by drag chains, which allows the displacement of larger particle materials, such as briquettes, for example, that are not tolerated in screw hoppers.

From 2 to 5 chains can be installed to carry out the transportation, with this amount varying by several factors, usually associated with the type of biomass to be transported and the desired storage capacity.

The greatest advantage of this model is that, if it is necessary to replace a set of chains for maintenance, the equipment can continue operating without interruption. In addition, the transportation speed can be adjusted by the frequency inverter so that the equipment reaches the designed nominal flow rate.

Technical specifications

| Models | MCAD/30 | MCAD/50 | MCAD/100 |

|---|---|---|---|

| Chain path quantity | 2 to 4 | 3 to 5 | 5 |

| Storage (m³) | Up to 30 | From 31 to 50 | From 51 to 150 |

| Width (mm) | 1500 to 4000 | 2400 to 4800 | 3500 to 5100 |

| Length (mm) | 3500 to 9700 | 5300 to 7600 | 9400 to 14300 |

| Height (mm) | 1200 to 2000 | 1200 to 2300 | 1200 to 2500 |

| Power (HP) | 7.5 to 30 | 10 to 100 | 50 to 150 |

| Flow rate (m³/h) | 30 to 200 | 50 to 500 | 50 to 800 |

| Weight (kg) | 11.200 | 14.000 | 20.600 |

The equipment can be adjusted according to your project's needs.

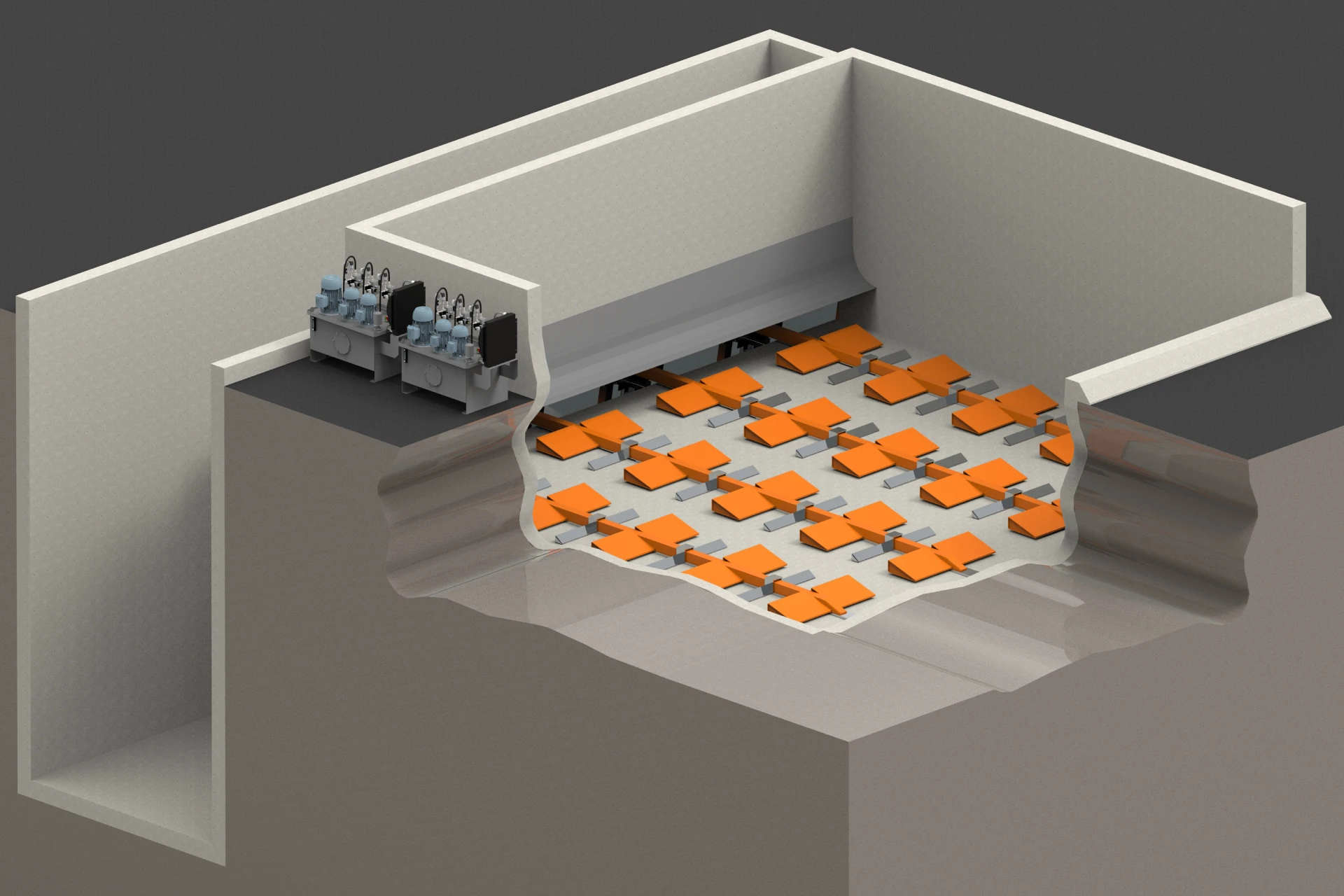

Live Bottom Hopper

The Moving Floor Hopper is equipment designed for receiving, storing and controlled feeding of biomass, especially suited to applications that require robustness and reliability when handling biomass with higher particle size and variable composition. Its design enables efficient reception of biomass regardless of its origin, acting as an essential intermediate point in the production line.

The moving floor system ensures continuous, uniform and controlled material flow, even under harsher operating conditions. This feature significantly reduces the risks of blockages, segregation or irregular discharge, directly contributing to the operational stability of downstream equipment such as conveyors, redlers and elevators, and ensuring greater reliability and efficiency for the production process as a whole.

With a robust structure and integrated mobility, the Moving Floor Hopper offers flexibility in plant layout, and is designed to integrate with projects that require civil works appropriate to operating conditions. Developed for continuous industrial use, it meets safety and quality standards, establishing itself as a durable and efficient solution for applications that demand high productivity, wear resistance and full integration with existing processes.

Hopper Accessories

Vibrating Grid

The vibrating grid uses motovibrators to facilitate the discharge of materials with difficult flow. Designed to prevent access to the machine's dangerous zone, this accessory was built in accordance with the requirement of the Brazilian Regulatory Standard NR12 - Occupational Safety in Machinery and Equipment.

For safety reasons, Dujua adopts the concept of fixed physical protection to ensure the health and physical integrity of its workers. In addition, this equipment is designed to prevent larger particles, such as stones and foreign materials, from entering the hopper and damaging it. It was developed based on the Brazilian Regulation NBR NM-ISO 13853 Machinery Safety - Safe distances to prevent access to danger zones by the lower limbs - constantly updated in accordance with current official technical standards and applicable international standards.

Technical specifications

| Modelo | GV-D |

|---|---|

| Quantity of motovibrators | 1 to 4 |

| Width (mm) | 1.500 to 5.100 |

| Length (mm) | 3.500 to 14.300 |

| Power (HP) | 1,5 to 1,75 |

| Weight (kg) | 1.600 to 4.000 |

The equipment can be adjusted according to your project's needs.

Automatic Cover

The automatic hopper cover is an accessory designed to prevent access to the machine's dangerous area when there is no incoming biomass, meeting the requirements of the Brazilian Regulatory Standard NR12 - Occupational Safety in Machinery and Equipment.

It is activated by a pneumatic system, which opens the cover to allow the unloading of fuel (biomass) into the hopper. The discharging area is properly marked and during the unloading process, audible and visual warnings are emitted, all following safety guidelines and procedures in accordance with current official technical regulation or applicable international standards to ensure the health and physical integrity of the workers.

In addition to its main function of providing safety, the cover also protects the biomass from the weather, such as rain, which can increase the moisture content of the biomass stored in the receiving hopper.

Technical specifications

| Modelo | CA-D |

|---|---|

| Drive type | Pneumatic |

| Cover type | Trapezoidal Tile |

| Width (mm) | 1.500 to 5.100 |

| Length (mm) | 2.500 to 14.300 |

| Height (mm) | 3.000 to 6.000 |

| Weight (kg) | 1.500 to 8.000 |

The equipment can be adjusted according to your project's needs.

Fixed Cover

The fixed cover is an accessory developed to protect the biomass from the weather, which can increase the moisture content of the biomass stored in the receiving hopper, or spread the biomass, and messing up the place.

Its installation is usually associated with the vibrating grid to ensure that the equipment is in compliance with Brazilian Regulatory Standard NR12 - Occupational Safety in Machinery and Equipment.

Technical specifications

| Modelo | CF-D |

|---|---|

| Cover type | Trapezoidal Tile |

| Width (mm) | 1.500 to 5.100 |

| Length (mm) | 2.500 to 14.300 |

| Height (mm) | 3.000 to 6.000 |

| Weight (kg) | 1.500 to 8.000 |

The equipment can be adjusted according to your project's needs.

Enclosed Cover

The enclosed cover represents an advance over the other covers mentioned above. In addition to offering protection against bad weather and ensuring compliance with current safety standards, the enclosed environment allows the installation of a dust removal system.

This system is equipped with overhead doors or curtains made of flexible material, which close automatically during the unloading of biomass. Inside of it, there is a system installed for capturing suspended dust generated during the biomass unloading process. The captured dust is then transported to an external bag filter, which redirects the biomass back to the transport line, keeping the environment clean and free of suspended particulate matter.

Technical specifications

| Modelo | CE-D |

|---|---|

| Closing type | Overhead Doors |

| Cover type | Trapezoidal Tile |

| Width (mm) | 7.000 to 16.700 |

| Length (mm) | 20.000 to 32.000 |

| Height (mm) | 6.500 to 14.500 |

| Weight (kg) | 11.500 to 25.800 |

The equipment can be adjusted according to your project's needs.

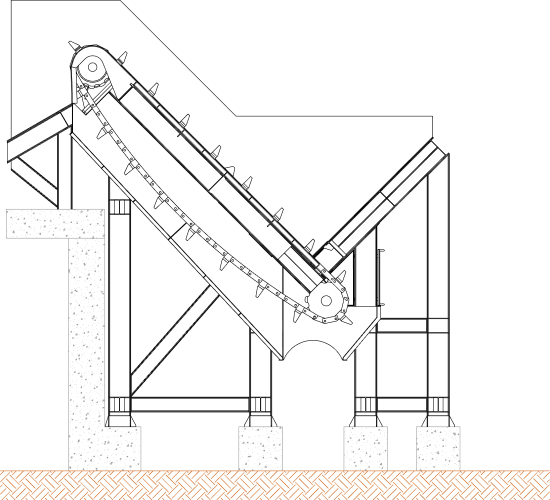

Receiving and Unitizing Table

Robust equipment with easy maintenance access, designed for continuous and constant operation.

The receiving and unitizing table is an equipment developed to receive and store logs from a horizontal conveyor table, fixed crane, mobile crane, loader, among others.

The logs are moved by drag chains, which move the logs gradually to the impact/chipping conveyor, unitizing the logs to ensure uniform and continuous feeding in the chipping line.

Technical specifications

| Models | MATD/3000 | MATD/4000 | MATD/6000 |

|---|---|---|---|

| Chain path quantity | 2 to 3 | 3 to 4 | 4 to 6 |

| Log Length (mm) | 3.000 | 4.000 | 6.000 |

| Width (mm) | 2.800 to 3.800 | 3.900 to 4.400 | 4.500 to 8.000 |

| Length (mm) | 3.800 to 7.000 | 3.800 to 7.000 | 3.800 to 7.000 |

| Height (mm) | 2.300 to 5.900 | 2.300 to 5.900 | 2.300 to 5.900 |

| Power (HP) | 6 to 10 | 6 to 10 | 6 to 10 |

| Flow rate (Ton/h) | 40 to 50 | 50 to 60 | 60 to 70 |

| Weight (kg) | 19.300 | 27.800 | 35.300 |

The equipment can be adjusted according to your project's needs.